“Convector GP” and “Convector GC” – water radiators

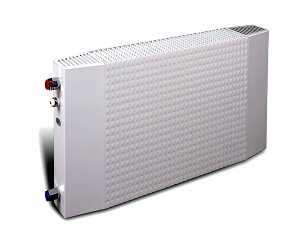

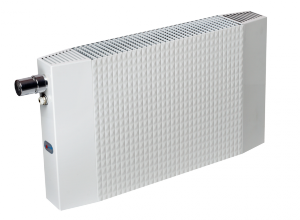

“Convector” offers the following water radiator types:

“Convector” radiators possesses a 20 years manufacturers guarantee.

![]() Convector GP & GC – Tables of heat outputs (according to EN 442), dimensions and price list 2017 (Acrobat Reader).

Convector GP & GC – Tables of heat outputs (according to EN 442), dimensions and price list 2017 (Acrobat Reader).

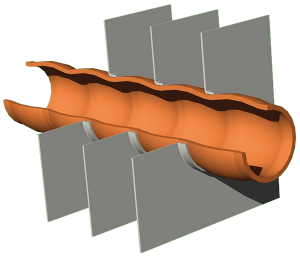

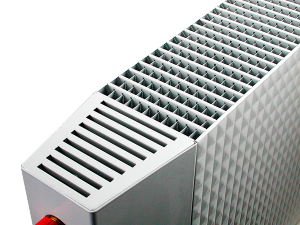

„Convector GC” radiator – internal structure

The heat exchange takes place inside of the radiator – exterior tactile temperature max. 50ºC

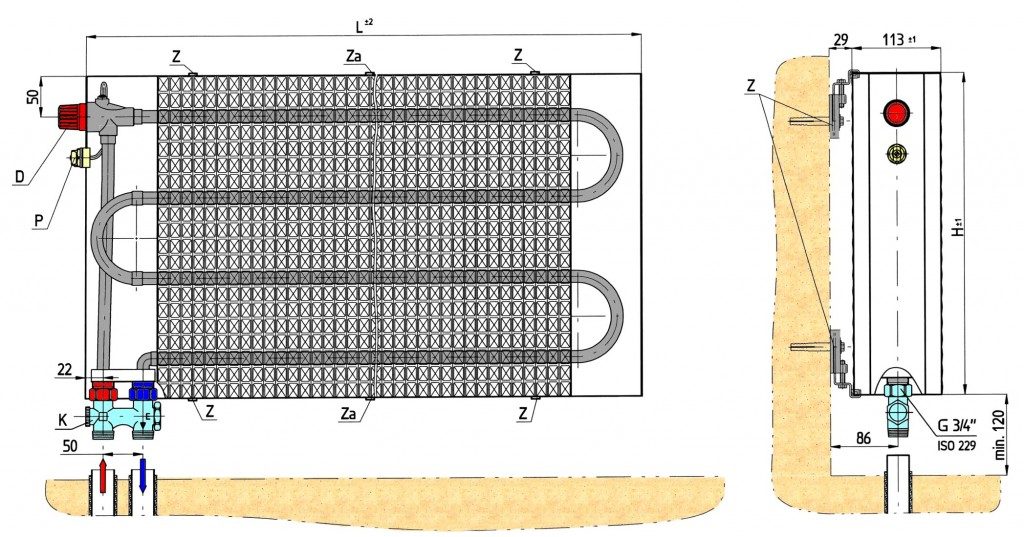

Construction details

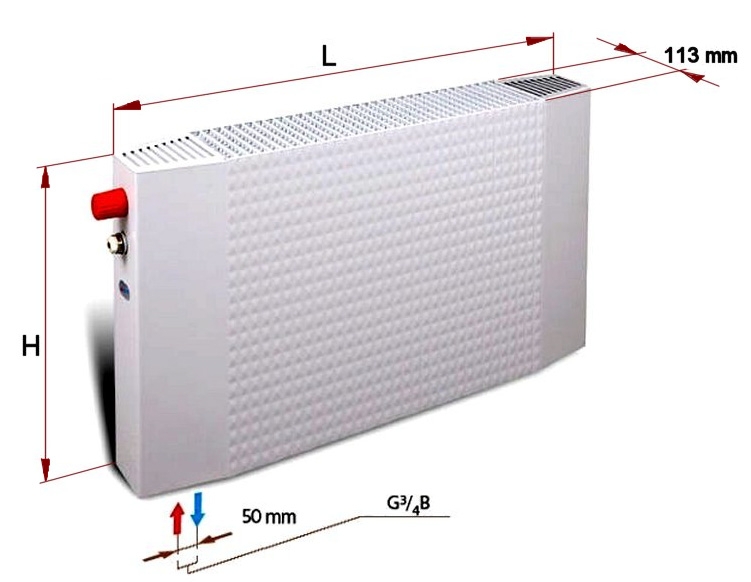

BASIC DIMENSIONS

TECHNICAL DATA “Convector GP & GC”

- Report on the COBRTI INSTAL nr 399/N/T/O/370

- The National Institute of Hygiene Certificate B-473/96

- The maximum working pressure 1.0 MPa (GP – max. 3.0 MPa on special orders).

- The maximum working temperature 100°C

- Connecting the radiator “Convector”:

Convector GP – side-fed – 2 spigots G1/2″ (ISO-228) (internal thread) spacing H1 = H(height radiator) – 100 mm,

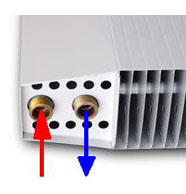

Convector GC – bottom-fed – 2 spigots G3/4″B (ISO-228) (external thread) spacing 50 mm, - Bottom-fed radiators (Convector GC) are fitted with the HERZ 98-V thermostatic valve with the maximum water flow as the default setting.

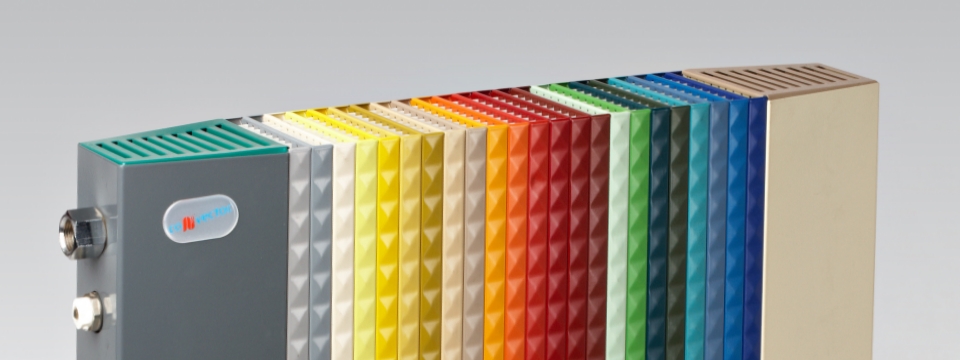

HERZ thermostatic heads may be connected to this valve (thermostatic head is not included). - White RAL 9003 is the standard colour of Convector radiators. Other RAL colours (ca.200) may be ordered.

- Each radiator is supplied with a set of brackets for wall mounting.

- The radiators GP and GC also can be supplied with special stands for direct floor mounting.

![]() EC Declaration of Conformity GP

EC Declaration of Conformity GP ![]() (Acrobat Reader).

(Acrobat Reader).

![]() EC Declaration of Conformity GC

EC Declaration of Conformity GC ![]() (Acrobat Reader)

(Acrobat Reader)

Radiators “Convector” – Convection – PERFECT HEAT

As distinct from traditional radiators, almost 85% of the warmth put into the air by Convectors is by convection guaranteeing a more efficient air circulation and even temperature distribution in the room. The small quota of radiation heat means that no unpleasant feeling of overheating in proximity to the radiator is experienced.

Convector’s radiator construction is characterized by the biggest heating surface obtaining the maximum power while allowing for the lowest temperature for the radiator itself, These features eliminate almost entirely the ill health effects of ionization, that bring about a feeling of suffocation and dryness of the respiratory traet, mouth, nose, larynx, headaches, soreness, and a rise in blood pressure.

Given this Convectors are ideal for the heating of flats, offices, hoteis as well as anywhere else where the health and comfort of the occupant is important.

Convector’s water capacity is notably less than that of traditional radiators, representing a marked reduction in heating delay and therefore lending itself perfectly to automatic heating systems. Every temperature change is instantly registered through the thermostat valve allowing large energy saving. As an example the delay factor in temperature regulation in Convectors is a matter of seconds as against minutes in traditional systems. In a correctly installed unit savings are in the region of 50%.